Information Sheet #9 - Analysis & Measurement of Electric Motor Vibration.

1.0 Introduction:

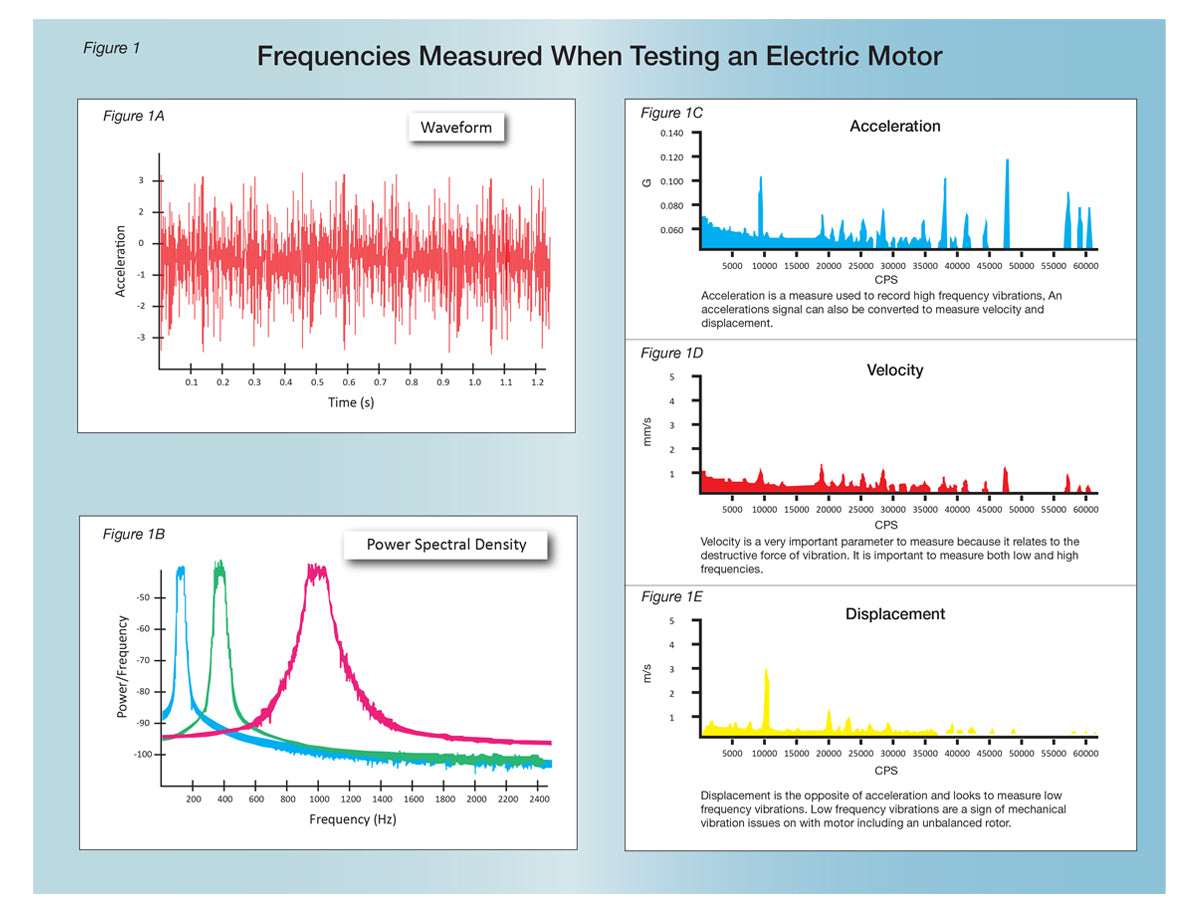

At some point in its life cycle an electro-mechanical device, such as an electric motor, will demonstrate vibration beyond a normal tolerance range. Vibration causes are numerous, including electromagnetic or mechanical imbalance, loose components, bearing issues, rubbing parts or resonance, refer to Information Sheet #08, Electric Motor Vibration Definitions and Sources within a Motor. Whatever the reason, it should be corrected quickly when detected and certainly during a routine maintenance cycle. Vibration problems can be irritating or a warning of impending failure. The strategy is to identify the vibration issues before equipment fails.

2.0 What is Vibration Analysis:

Vibration analysis is the process of measuring the vibration levels and frequencies of the electric motor and using the results to analyze how healthy the motor and its connected equipment is versus normal tolerance. The manner in which vibration is determines vibration can be complex, but it all starts with using an accelerometer to measure vibration. All motors vibrate to some degree, an accelerometer attached to the motor generates a voltage signal that corresponds to the amount of vibration and the frequency of vibration the machine is producing, usually how many times per second or minute the vibration occurs.

Also in Information Sheet Blog

Information Sheet #13 – NEMA Motor Repair, Best Practice & Definitions